Die And Mould Industry Meets In June Of China

The Chinese die and mould industry will meet in June at Die & Mould China. Currently, China’s die and mould industry is in a critical period of quality improvement, efficiency increase and steady progress. China’s die and mould enterprises are all well-equipped, and the die and mould manufacturing ecosystem is healthy, which has a significant function of benefit amplifier for the downstream product manufacturing industry.

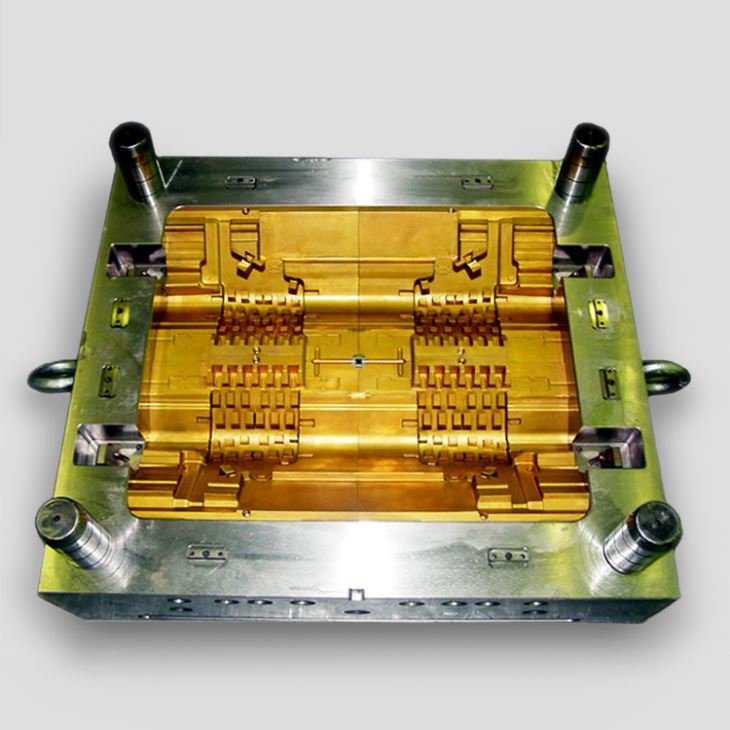

This is custom heading elementDescriptionFeedbackDescription Product description Advantages: 1. Competitive price 2. Strict quality control system 3. Quick mold making and delivery 4. Advanced equipment, excellent R&D teams 5. Professional technicians and rich experienced workers Item Description 1.Mould material P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 2.Hardness of steel vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 3.Inserts / Slider steel…

Customizing Car Dashboard Covers With Injection MoldDescriptionFeedbackDescription Cavity/Core Material 718H, P20, NAK80, 2316,2738,Din2344,H13 and available Product Material ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. Base (HASCO) German , FUTABA Japan, DME US, LKM China or by requested Structure Double color injection mould, Solid…

This is custom heading elementDescriptionFeedbackDescription Casting Mining Lamp Shell The cover for Miner’s Lamp, aluminum, die casting, electrophoretic painting Aluminum Housing for Miner’s Lamp with heat sink 1. Unique design for heatsinking 2. Process of die casting and cnc machining gets a pefect shape 3. Special surface finish as electrophoretic painting makes the whole part…

This is custom heading elementDescriptionFeedbackDescription Product name Precision Injection Mold Tooling Mold Type Plastic Injection molding Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.02mm Finish Anodized,Polish,Silk-screen,Painting,etc Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Mold life 300,000-1,000,000shots Lead time 25-45 days Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable Certificate ISO9001 FAQ Q1: Which kind information need for quotation? A1: 1) Sample photo with size or 2D/3D design 2) Product material 3) The quantity 4) Runner type, cold or hot 5) Mould steel type,…

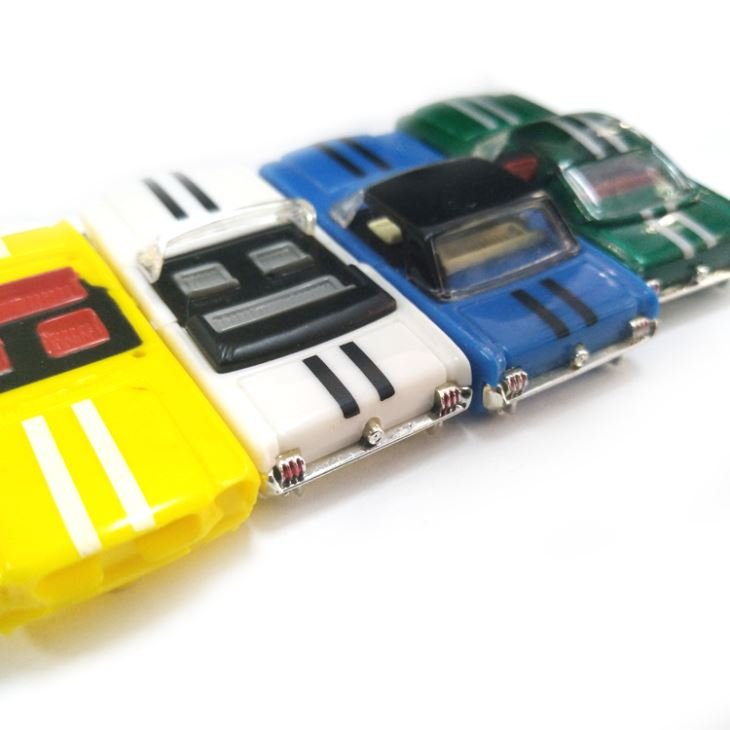

This is custom heading elementDescriptionFeedbackDescription Scale Model Cars Many miniature vehicles were originally aimed at children as playthings. But Precision-detailed miniatures made specifically for adults are a significant part of the market now. Fit Precision Mold Co., Ltd is specialized in producing all kinds of plastic scale model cars and accessories in different scale size,…

This is custom heading elementDescriptionFeedbackDescription Airbag cover injection molding Airbags have to be protected from damage to ensure their reliable deployment throughout the vehicle’s life cycle. The airbag protection solution should take up as little assembly space as possible and enable cost-effective production and assembly. Fit Precision Mold Co., Ltd 1 Company’s strength…

This is custom heading elementDescriptionFeedbackDescription Product Name Professional OEM Plastic Mould Molding Service Maker Core &Cavity Steel P20,718H,2738H, H13, NAK80,2316 etc. Mould base & Standard Component DME,HASCO,Self-made etc. Steel hardness: HRC35-38 Plastic material PP,PC,PE,ABS,PVC etc. Cavity Number 1*1 Injection System Side Gate,hot gate Ejector System Ejector Pin Cycle Time 30-60S Tooling lead time 45-60 Days Mould life 500,000 Shots Quality assurance ISO9001 FAQ 1. Q: Can you provide the steel certificate and heat-treatment certificate? A: Yes, We can provide steel…